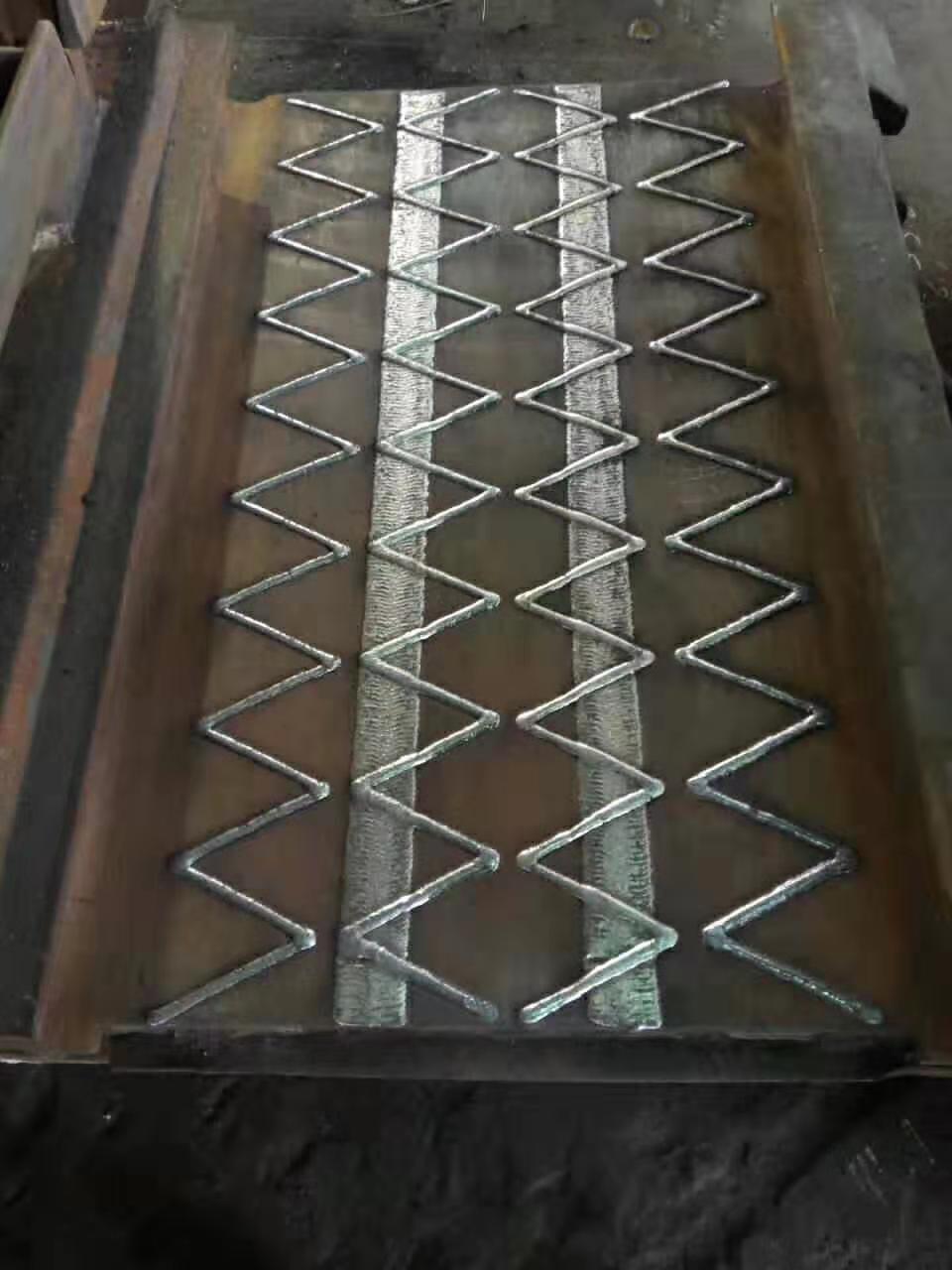

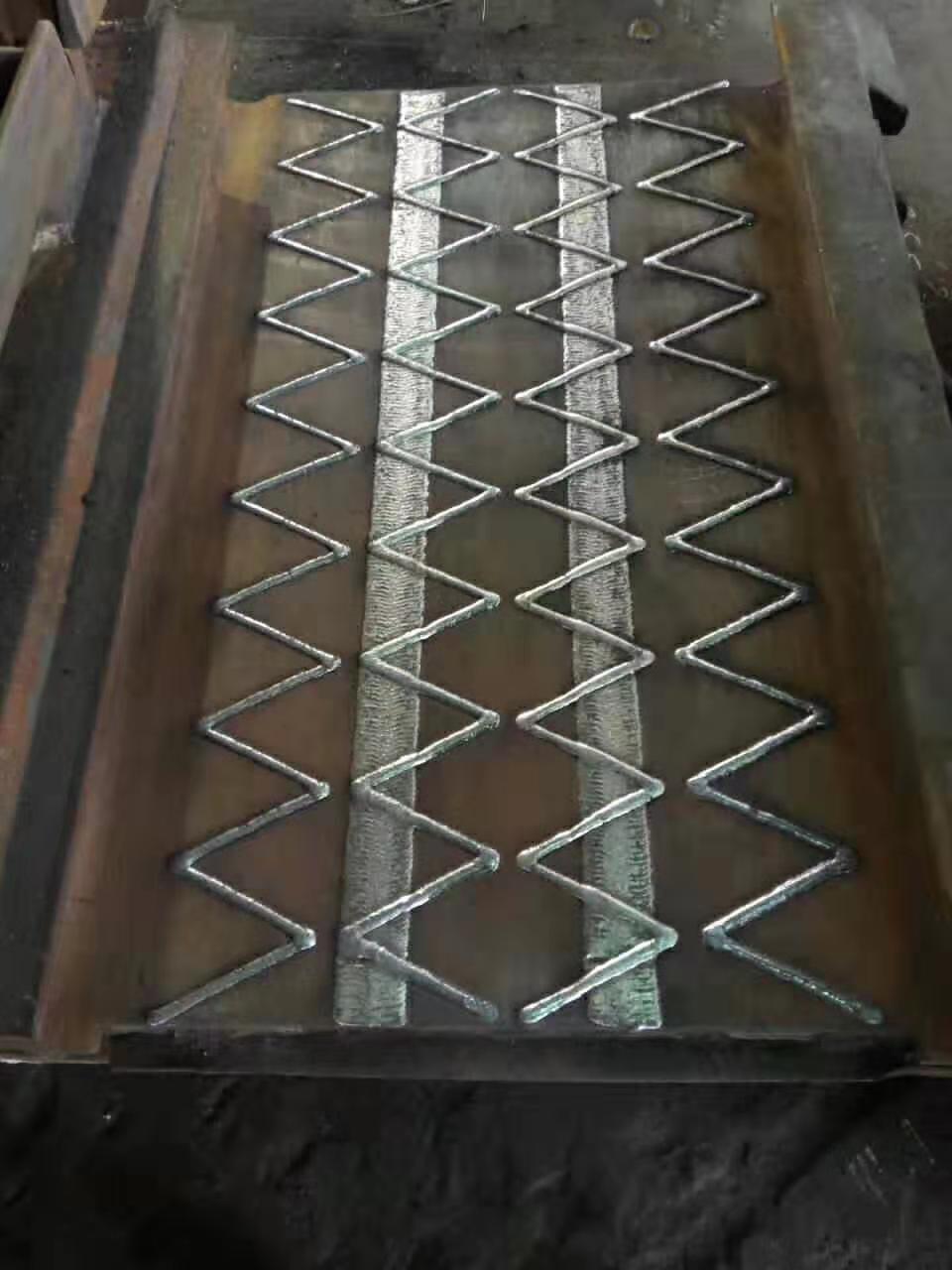

Product introduction:

Surfacing repair workpiece: scraper, middle groove

Welding wire model: self-protection series welding wire

Welding wire diameter: 1.2-2.8mm

Welding method: Self-shielded/Gas shielded

Features: TM570 wear-resistant plate surfacing welding wire has the characteristics of excellent welding process performance, beautiful welding seam shape and less welding spatter. There is no need to use gas or flux protection during welding, which simplifies the welding process and saves the cost of welding accessories. The metal of the surfacing layer is a high-chromium molybdenum alloy, and fine cracks will appear during surfacing, which is the result of stress relief and does not affect the normal use under low-impact industrial and mining conditions.

Uses: Used for surfacing workpieces that are subjected to strong abrasive wear under slight or no impact, such as wear-resistant liners, chutes, material clocks, screw conveyor impellers, mining machinery and building materials machinery, etc.