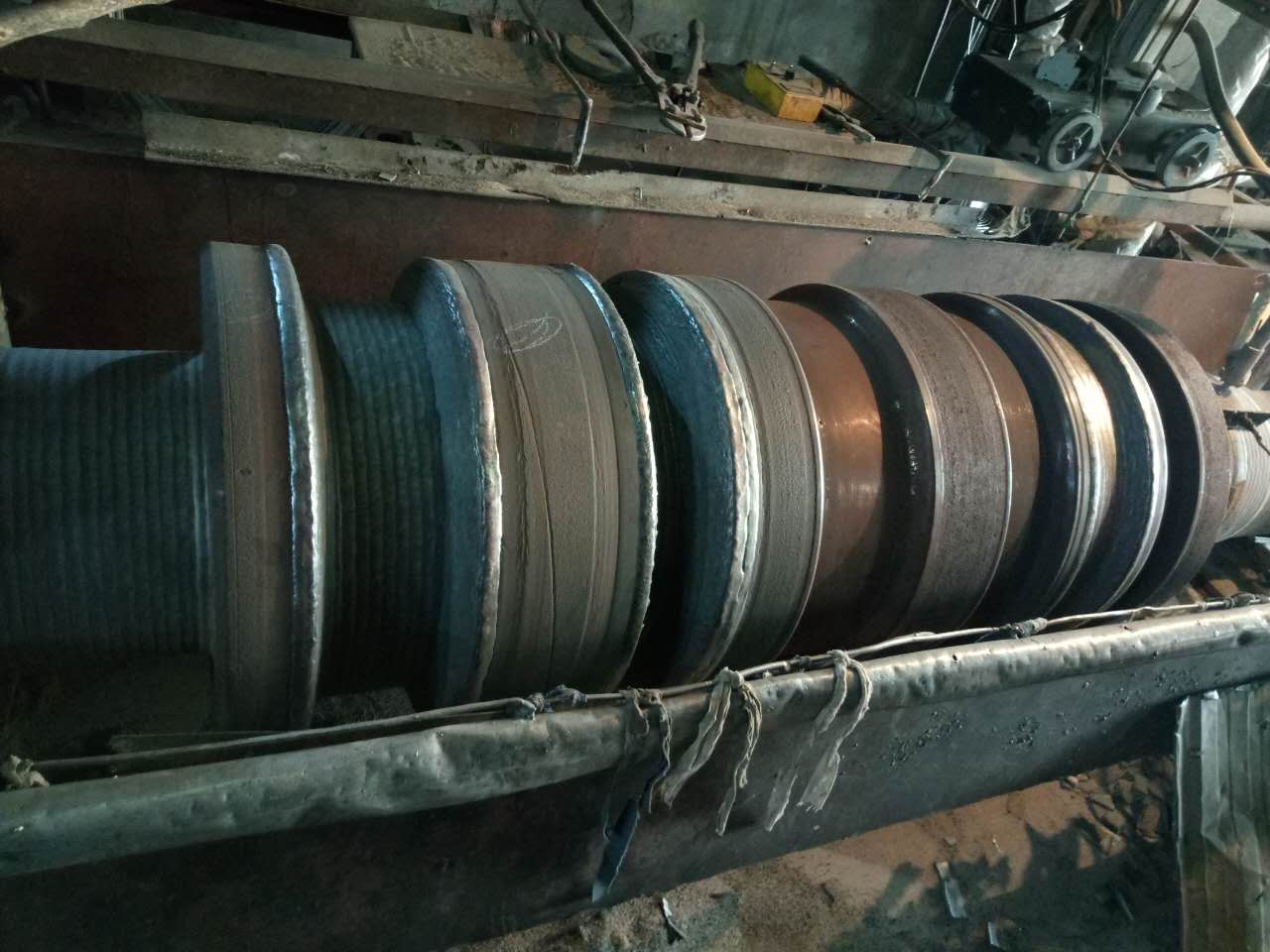

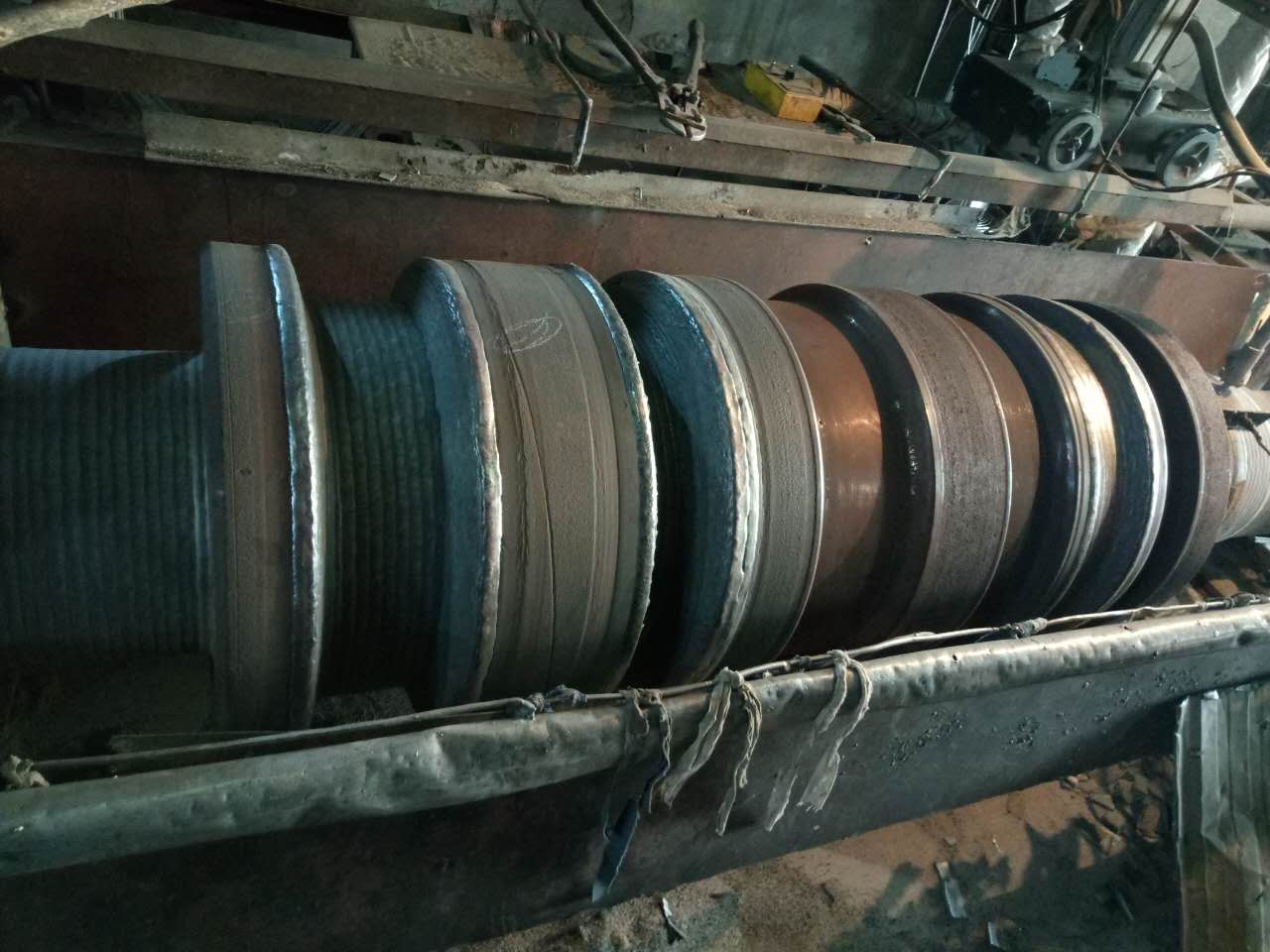

Hot Rolling Cogging surfacing repair

Surfacing repair workpiece: hot-rolled billet roll

Welding wire model: TM552

Wire Diameter: 24.0

Welding method: submerged arc welding

Surfacing flux: TecMig brand flux

Recommended Wire Welding Wire and Features:

TM551 is a flux-cored wire for submerged arc surfacing welding. The wire is connected correctly during welding. With HJ107, the welding process performance is excellent, the shape is beautiful, and the slag removal is easy. The metal of the surfacing layer is chromium, tungsten and low carbon alloy, which has the effect of precipitation strengthening. At high temperature, disperse carbide is precipitated, which can maintain good high temperature strength and hardness, so it has excellent tempering resistance stability and wear resistance.

Surfacing process:

1. Before surfacing welding, remove the fatigue layer, and perform preheating, heat preservation and slow cooling as required.

2. The flux is dried as required.

3. Strictly control the welding current, voltage, welding speed and other process parameters.

4. Control the interlayer temperature not lower than the preheating temperature.