Ø Shielding gas: CO2 100%.

Ø The metal properties of the surfacing layer: the wear-resistant material wear and the intermetallic wear resistance are better.

Ø Operability/manufacturability: small splash, no pores, no cracks, beautiful shape.

Ø Applicable base metal: Q235# or similar grade steel

Ø Surfacing thickness limit: 4mm or more.

Ø Crack resistance: good. However, it depends on the base metal material, workpiece size, welding thickness and welding process.

Ø Machinability: can be turned. .

Ø Optional diameter and packaging form: φ 1.2/Ф 1.6, 15KG plate.

Track boards surfacing repair.

Technical indicators

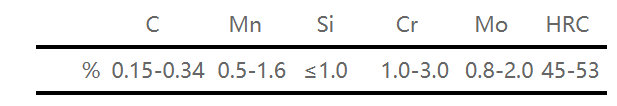

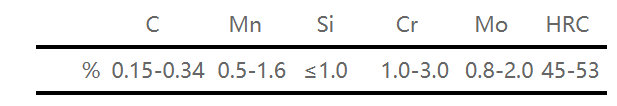

Ø Typical chemical composition (%) and hardness

Note: The hardness value is the value above 10mm for surfacing welding.

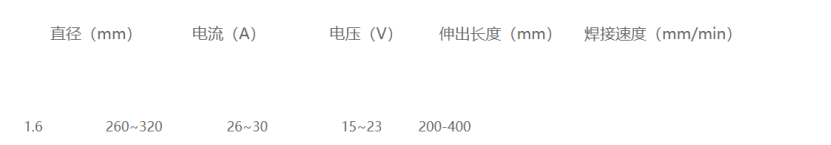

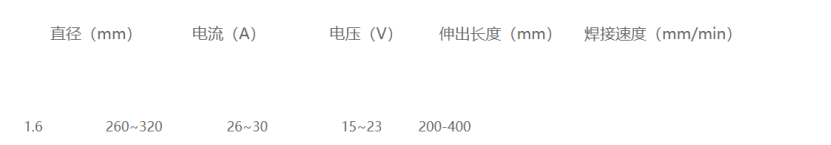

Ø The best parameter range:

Ø Ф 1.6 Diameter deposition rate (utilization rate): 88.1 % (corresponding to the high value of the optimal current)