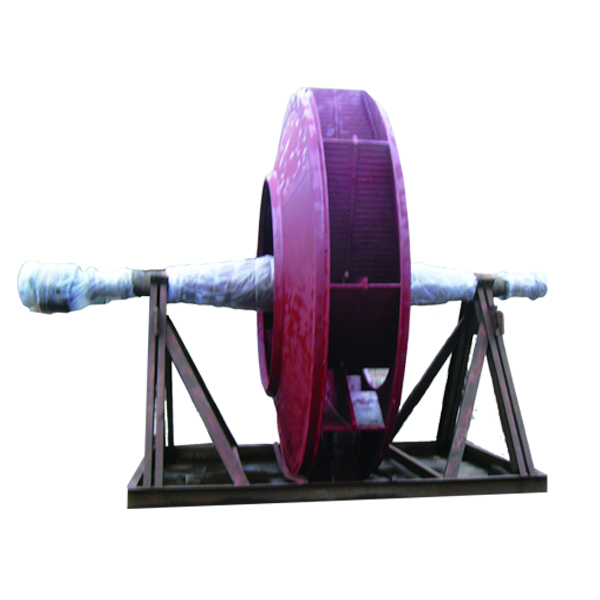

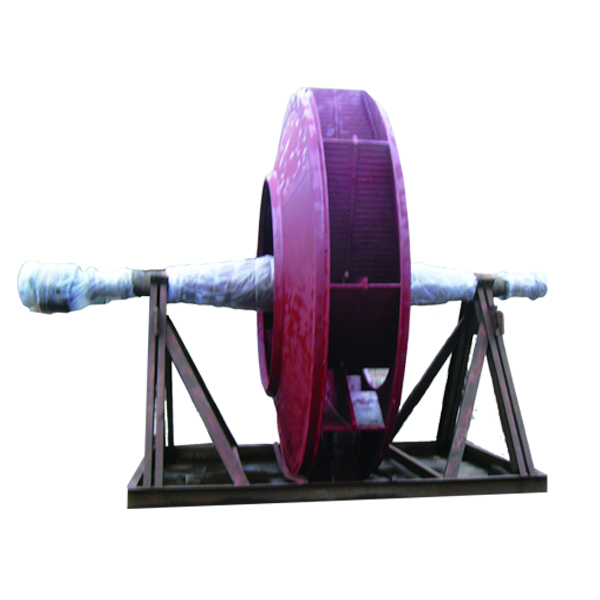

Surfacing workpiece: fan impeller

Welding wire model: TM605

Welding wire diameter: 1.2-1.6

Welding method: gas shielding

Welding wire features:

TM605 flux-cored wire is CO2 or 80%Ar+20%CO2 protected wear-resistant surfacing flux-cored wire. The welding wire has excellent welding performance, beautiful shape, less spatter, and the welding efficiency is more than 3 times that of manual welding rod. The deposited metal is high-chromium alloy, and the metallographic structure is martensite plus alloy carbide. Because the carbide has extremely high hardness, it has excellent wear resistance of wear-resistant materials. When the wire is surfacing, fine cracks will appear, which is the result of stress release, and will not affect the normal use under low-impact industrial and mining conditions.

Scope of application:

It is used for surfacing welding workpieces that are subjected to strong abrasive wear under slight impact, such as coal mill grinding rollers, chutes, material bells, mining machinery and building materials machinery.