How good quality welding rods E6013 is produced by TecMig:

E6013 is a mild-steel, all positional, general purpose rutile-based rod. It operates on AC or DC welding current and works well on low voltage AC machines. E6013 is an excellent choice where there is poor fit-up in the joint. It deposits easily and smoothly producing medium to shallow penetration. Small sizes are well adapted to low heat and thin metals. Medium to heavy slag is easily removed and provides for excellent weld cleaning action during the welding process.

It is once the biggest seller in almost all the markets in the world. But now as welding efficiency is getting more and more important, the overall welding rods consumption is getting smaller and smaller, so is the E6013 consumption qty.

But it is still a very important welding product in most of the markets.

TecMig (TM Welding), as a professional welding rods manufacturer with over 20 years expertise, no tell you how good quality welidng rods E6013 is produced:

1, Raw materials:

The most important raw materials include wire rods & rutile.

According to AWS standards, core rods of E6013 should be H08A from reputed steel factories like Sha Steel Group, Xiang Steel Group, etc to ensure the chemical compositions/ mechanical properties of electrodes comply with AWS standard.

Some factories use Q195 steel, which is made from recycled steels, to cut the costs. But because there are too many impurities in the core rods, the mechanical properties / chemical compositions can’t meet the requirements of AWS A5.1 and the weldability is not so good as E6013 produced with H08A.

TecMig never compromise to use Q195.

There should be a big amount of rutile in the flux coating of E6013, as rutile is very important for arc ignition, arc stability and vertical down welding performance in E6013 welding.

Most of other factories in China use lower grade rutile like 65%, 75%, etc, but we TecMig only use 85% grade rutile in standard E6013 and 95% rutile in vertical down type E6013.

Some factories even use much cheaper reduced titanium to replace rutile, though the costs are much lower, the weldability are quite different.

TecMig, same as many other international welding brands like Esab, Lincoln, Indura, Infra etc, sticks to the traditional rutile type formula, and won’t change to reduced titanium.

And this is why TecMig is liked by many international welding brands and be called “ the unsung hero behind many reputed international welding brands ”.

2, Formula

Formula is of vital importance in E6013 production.

Different combination of powders in the flux coating leads to very different welding performance . And the relationships between different powders are very subtle, for example, adding wood powder can cut the costs and improve the flux coating quality, but it also brings very disgusting smell in welding. So we have to try different combinations of powders to find the balance among arc ignition, arc stability, minimum spatter, less welding fume, vertical down welding performance, arc force, weld bead formation, anti-moisture performance, etc.

TecMig has over 20 years experience in welding rods formula research, and our R&D team knows well about the subtle relationship between different alloys and minerals, has developed different formulas to meet different performance requirements for different markets.

This is also part of the reasons why so many international welding companies come to ask us OEM manufacture for them.

3,Quality management

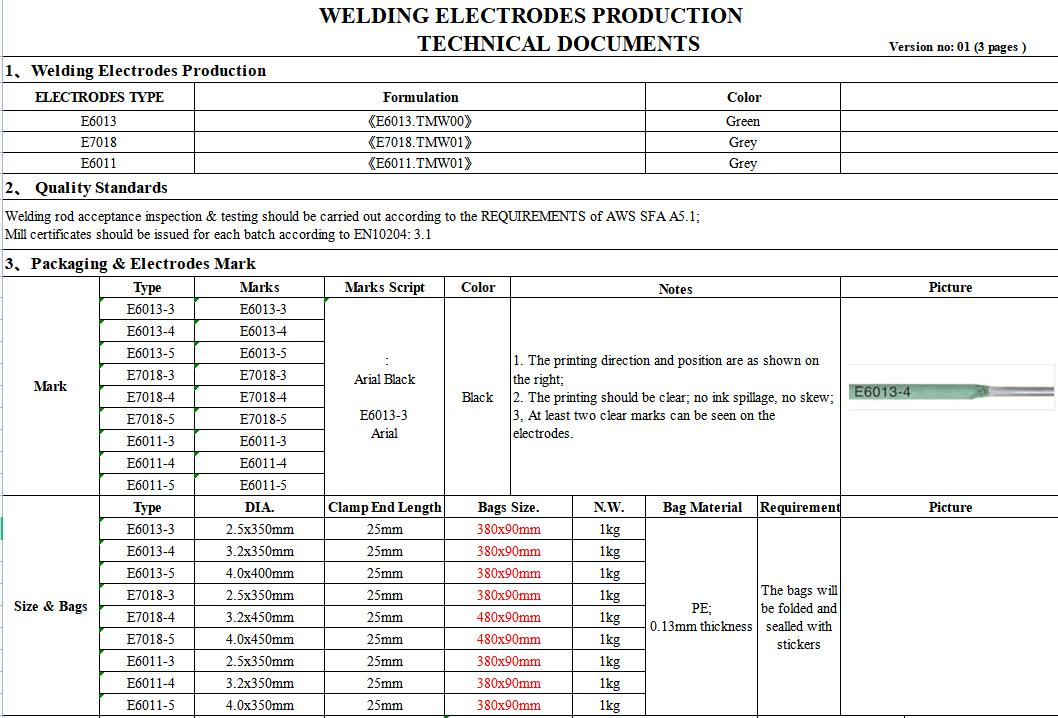

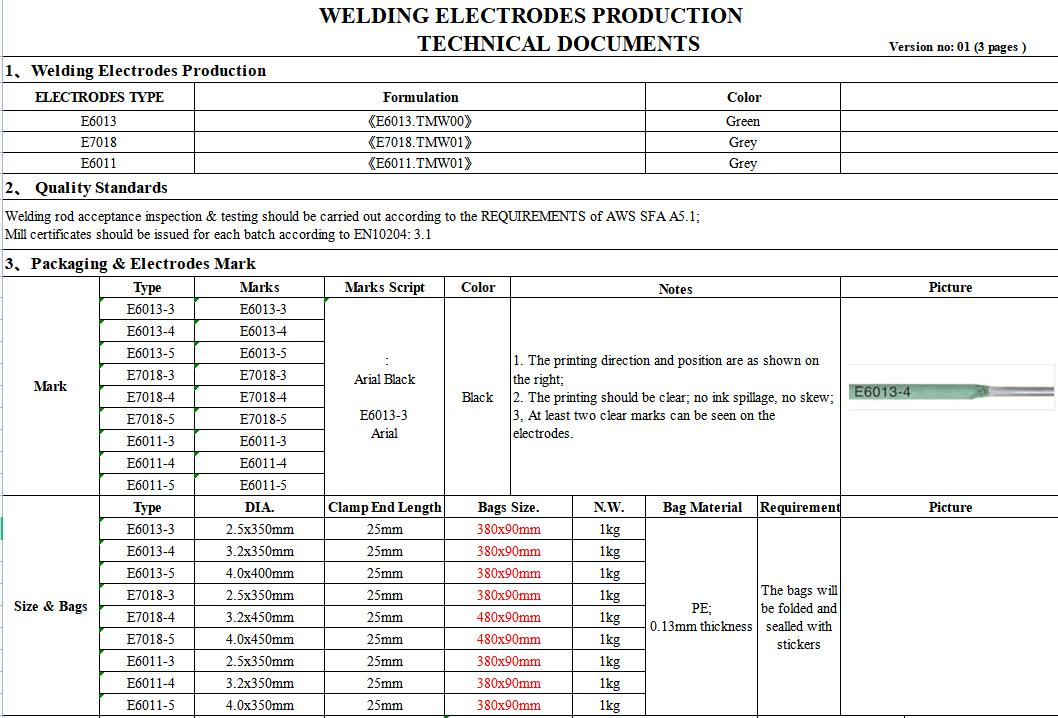

1) Documentation

Once the samples are approved by our customers and they place an order to us, many production standards will be drafted. From these paper, our workers can easily learn all the details concerning the production of this brand orders, including raw materials/ process procedures / packaging details / delivery requirements, etc.

The details can be as big as formula, the drying temperatures of different electrodes and as small as the fond of the letters on stickers.

Pls see below examples of part of the papers:

This can ensure everyone in our factory knows how to produce welding electrode under a certain brand.

2) In process inspection

The electrode flux coating are easily damaged by the conveying belts during the production.

We have 2 people before and after the drying process to inspect the electrodes and pick up the damaged ones, this ensures less than 2% of damaged electrode percentage.

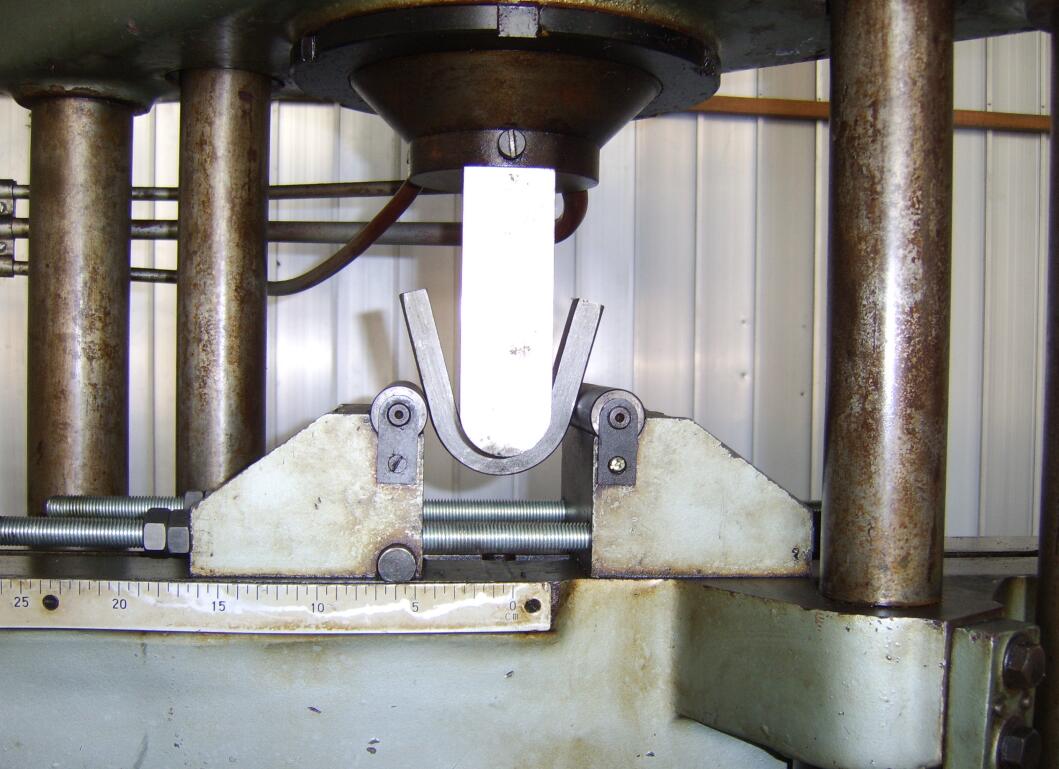

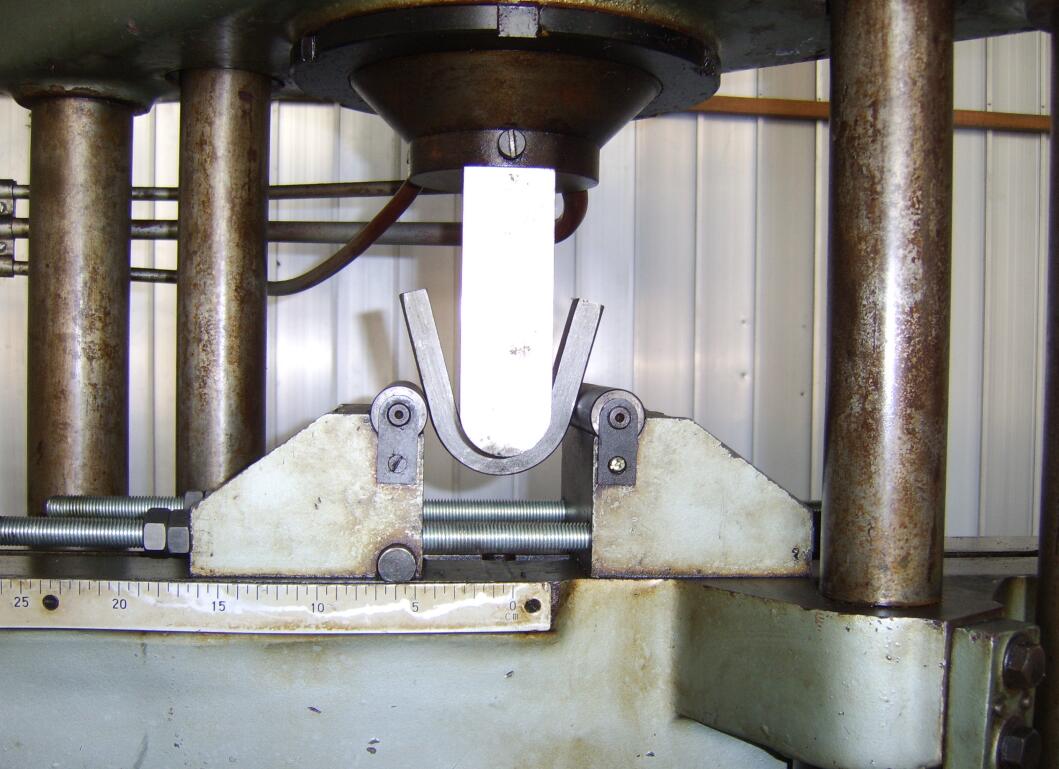

The eccentricity is important to ensure the arc stability, so our electrodes will be tested from time to time to ensure the eccentricity complies with our standard.

Electrodes drying temperatures are very important during the production, as the electrodes should be dry enough to obtain good weldability and a certain amount of water should be kept in the flux coating to assist in ignition.

And different electrodes should be baked with different temperatures.

Our ovens temperatures are automatically monitored to ensure the temperatures are not too high nor too low.

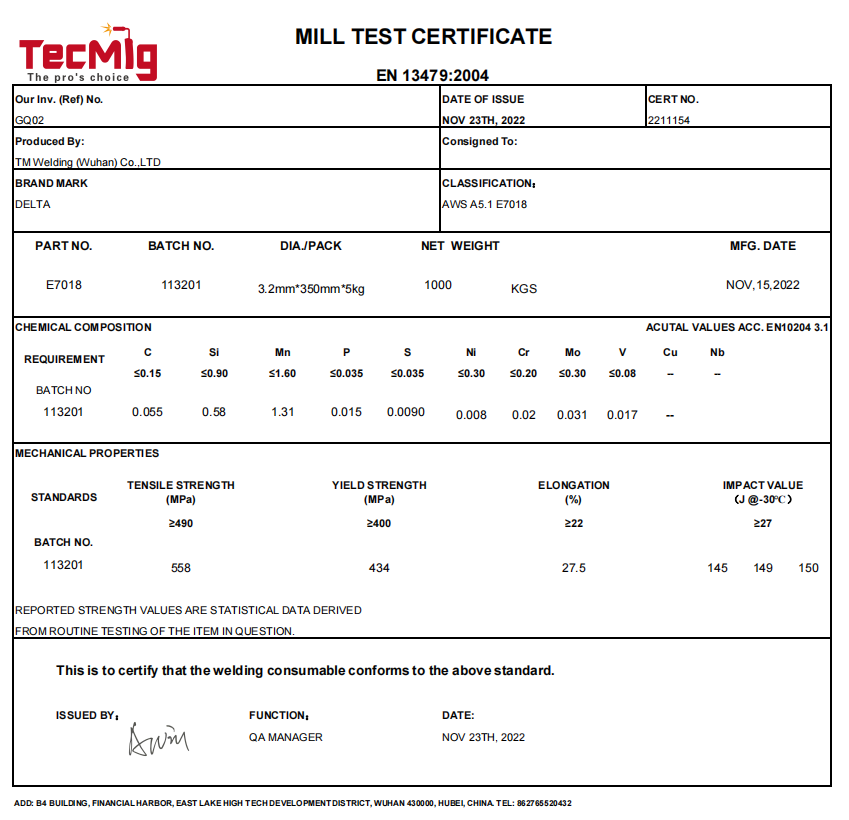

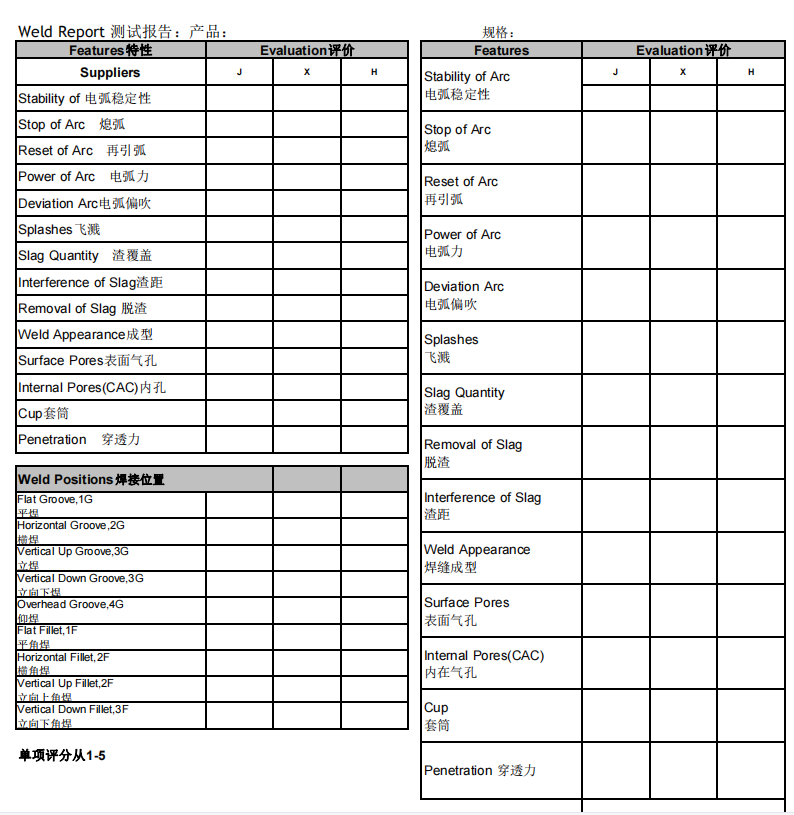

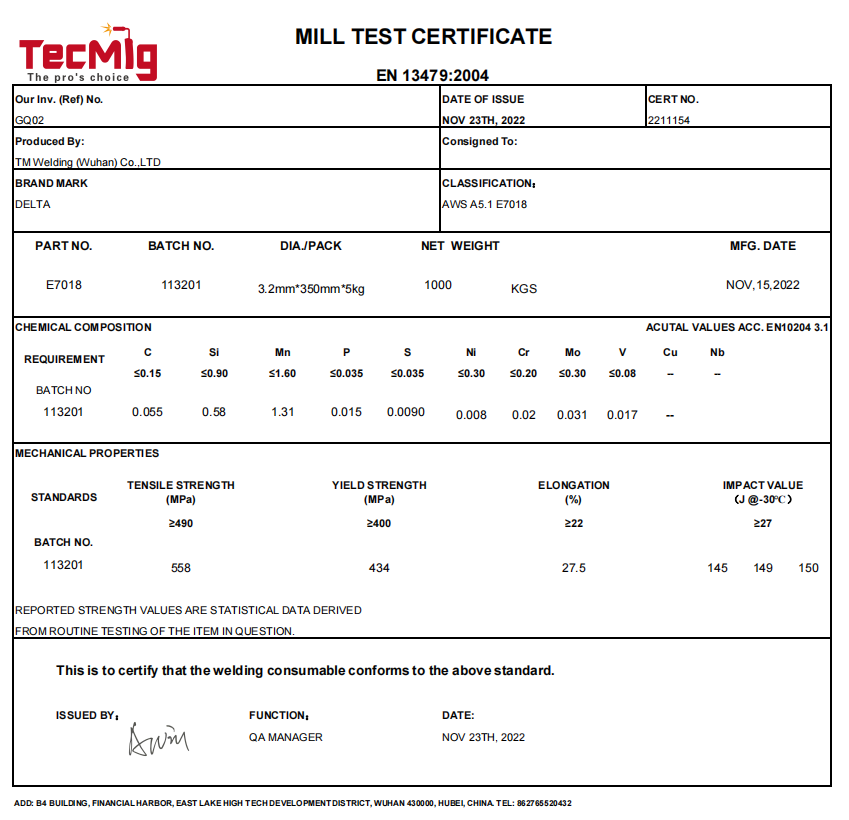

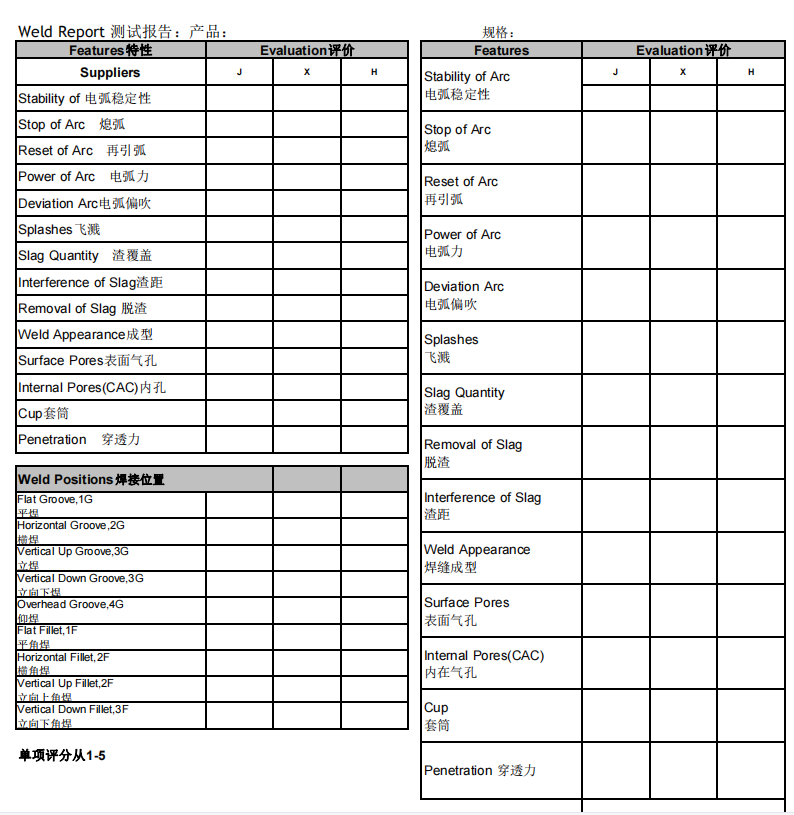

3) Finished products testing

Samples will be taken from each batch of electrodes and the weldability (including slag coverage, slag removel, spatter, arc force, bead formation, welding fume, ignition, etc), chemical composition, mechanical properties will be tested to ensure they comply with AWS standards and can meet customers’ requirement.

Above are how we produce good quality E6013, you are welcome to inquiry us on more details of our quality management.